Making bee feeders with your own hands is not a difficult task even without tools. It is easy to make from improvised means. A bee feeder from a plastic bottle or glass jar can be made in a couple of minutes with a minimum of effort.

Let’s consider the main types and requirements for the product.

What are feeders for?

Bees need additional feeding if they do not have enough food. Food shortage can lead to the death of insects. It is worth remembering that the feeder is not installed permanently – it should be at hand so that in an unforeseen situation (both in winter and summer) it can be used for its intended purpose.

There are several situations in which you cannot do without a bee feeder:

- feeding with flavored syrups (performed to train bees to new honey plants);

- creation of a new apiary (insects need support, since they are not familiar with the new area and honey crops on it);

- feeding with medicinal compounds;

- the onset of winter (sometimes additional feeders are installed in the fall, before the onset of frost, so that the bees are better prepared for winter).

Requirements for the feeder

Bee feeding structures can have different sizes and shapes, but the standards for them are the same and look like this:

- the capacity of the feeder should be up to 4 kg;

- insects must have free access to food at any time of day and in any weather;

- bees should not drown in sticky syrup while feeding;

- When feeding, any contact with insects is excluded;

- the beekeeper has the opportunity to assess the volume of syrup remaining in the feeder in order to add a new portion as needed;

- the design is easy to maintain, as it will need to be cleaned and washed regularly in the future;

- Insects from neighboring hives are blocked from accessing the contents of the feed tank.

If the feeder is poorly designed, it is dangerous for the bees, as they will drown in the syrup, get injured or overcooled, which will ultimately lead to a drop in the hive’s yield.

Types

There are a large number of models of bee feeders, which can be made from a variety of materials – wood, plywood, metal, plastic and even foam. At the same time, these designs are conventionally divided into several types, which we will consider below.

Ceiling

This type of feeder is perfect for multi-body hives, as it can be easily installed under the ceiling. It is a rectangular body, the interior of which is divided by vertical partitions.

When making it yourself, experienced beekeepers recommend taking into account the following nuances:

- As internal partitions You can use splinters and twigs. However, you need to have some experience working with these materials, since there is a risk of bees dying on sticky splinters.

- Additionally, you can make a raft from four-layer plywood, the size of which is 4 mm smaller than the feeder itself at each edge. In this rectangle, you need to cut paths 3-4 mm wide, and then cover everything with wax. This raft is very convenient for the shoulders, since they do not get dirty and do not get stuck in the syrup.

- You can make a canvas of a small distance in the feeder, so that the bees cannot get inside. The box should be covered with glass or a pillow. To fill the container with food, it is enough to move this partition.

- To pour syrup into the feeder, it is convenient to use funnels. This will be possible if you initially make a hole in the feed compartment of the appropriate size.

It is better to hang a ceiling feeder in the summer so that the bees receive stimulating feeding. Initially, you can use the strained cappings. The bees will take honey from it and begin to build honeycomb cells, which will later serve as rafts.

At the end of December, insects should be fed with dissolved honey, which should fill half of the feeder. Every few weeks, it is necessary to check the nest to replenish the food supplies in time. This should be done until the cleansing flight.

The ceiling feeder is easy to use and has a comfortable structure for bees, since they do not drown in syrup. In addition, it allows you to maintain the optimal temperature of the feed, since the bees warm it during flights.

Framework

This feeder is a small wooden container, open at the top. It has the length and height of a regular honeycomb frame, but is slightly wider.

It is installed in the hive in two ways:

- placed on a special mat;

- They are hung on the wall near the nest using special protrusions on the upper bars or hooks.

Sugar syrup is poured into the frame feeder through a funnel. To prevent insects from drowning during feeding, a special raft or grate should be placed inside the container.

Overframe

This is a box-type feeder that is placed in the hive above the frames. It completely encloses the bees’ nest, so they have no opportunity to fly out during feeding. It has 2-3 sections, one of which serves as a passage (8-10 mm), and the rest are cells for filling with sugar syrup or honey.

The materials used to make the feeder box are not afraid of corrosion. These include wood, aluminum and plastic. The shape of such a box should be rectangular, and the volume should be from 0,5 to 2 liters.

The top wall of the box is installed in such a way that its upper edge rests against the lid, and a gap of 2-5 mm is formed at the bottom for the flow of feed. The above-frame model can be covered with plywood, glass or other transparent material from above to control the volume of syrup or honey. Holes must be made in the lid for feeding.

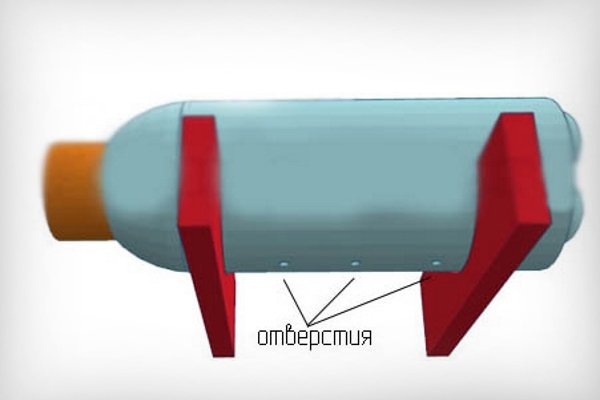

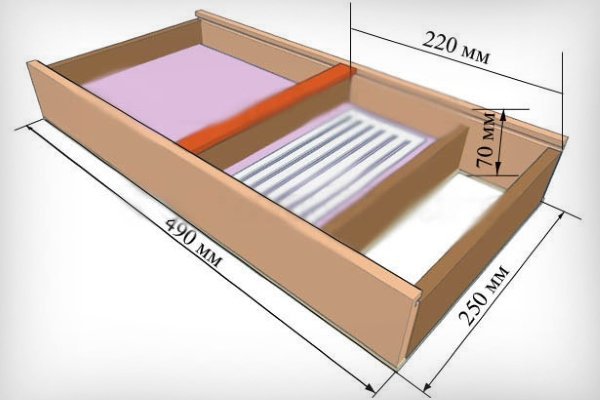

A similar design is shown in the photo:

Such a feeder should be installed on the canvas, directly above the hive frames. In this case, the gap for the feed must necessarily pass across the frames. In order for the bees to get into the feeder, a small hole should be made in the canvas opposite the entrance.

The container can be filled with food in a thin stream through the outer opening. To attract the attention of insects, you need to drip food in front of the bee entrance and on the frames. After that, the feeder can be closed with a lid and insulated with a pillow.

Outdoor

When making it, you need to take into account the following rules:

- To ensure free entry of insects into the box, you need to make a small hole in its back wall.

- You need to put a special bowl in the container itself. for filling with food. You also need to put a raft in it so that the bees are completely safe and do not drown in the syrup.

The finished feeder can be hung on the back wall of the hive or installed at some distance from it, and then filled with syrup and, if desired, add branches, rafts or grass to it. Thus, the feeding process is very simple, especially if there are no other apiaries nearby.

An external feeder has a significant drawback – the feed in it quickly cools down and stops attracting bees. In addition, it is quite difficult for a beekeeper to control the amount of feed received by a particular family.

How to make bird feeders from a plastic bottle?

Such feeders are considered a real find for beekeepers, since they do not require large expenses for production and have a simple structure, but at the same time allow free control of the feed supply due to the possibility of sealing excess holes with tape. In addition, such designs are very easy to use, since they are easy and quick to wash.

Feeders made from plastic bottles are an ideal option for hives with a low lid.

It should be noted that plastic intra-hive feeders can be horizontal and vertical. How to make each of them, we will consider separately.

Horizontal

To make such a feeder you need to prepare:

- a 2 liter dark plastic bottle;

- Scotch;

- nail (awl) with a diameter of at least 1,5 mm;

- pencil or marker.

The product is assembled in the following order:

- On one side of the bottle, closer to the neck, draw a line and at the same distance from each other depict 5-7 dots with a diameter of 1,5 mm.

- Put the bottle down Make holes in the marked points with a flat blade and a hot nail. The insects will feed through them. The diameter of the holes is 1,5 mm, which is optimal, as it will allow the bees to easily reach the food without falling into the feeder.

- Prepared holes seal it with tape and then pour syrup into the bottle.

It is better to make the holes with a hot nail, since in this case they will have melted edges, so the insects will not get injured while feeding.

The finished feeder can be installed in the hive in two ways:

- From two wooden blocks make supplies on which to place a bottle of syrup horizontally, so that the holes are facing down. Place the feeders inside the hive, and then remove the tape.

- On the ceiling of the hive prepare a place for the installation of the feeder – a hole cut in the shape of the bottle, but smaller in size, otherwise the container will fall on top of the honeycomb frames. In the prepared opening, you need to install the feeder with the holes down, and then remove the tape.

It should be noted that the feeding syrup has a viscous consistency, since the sugar concentration in it is about 60-70%. Due to this, it will not flow out of the reservoir too quickly, so the bees can feed on it without any obstacles or restrictions on quantity.

The vertical

To create a vertical feeder, you will need the same items as in the previous version, namely:

- plastic bottle with a capacity of 1,5-2 liters;

- nail (awl);

- pencil or marker;

- Scotch.

A similar container is made as follows:

- At a distance of 1-3 cm from the bottom of the bottle make holes with a diameter of 1,5 mm using a hot nail. It should be taken into account that the thicker the dressing, the more holes need to be prepared. There can be up to 12 of them in total.

- Seal the holes with tape. In the future, using such manipulation, you can regulate the number of holes, that is, the rate of consumption of the feed.

- Pour the syrup into the bottle through the neck 3/4 full and screw on the lid, then turn it upside down.

- Place the container vertically in the hive between the wall and the frame, and then remove the tape.

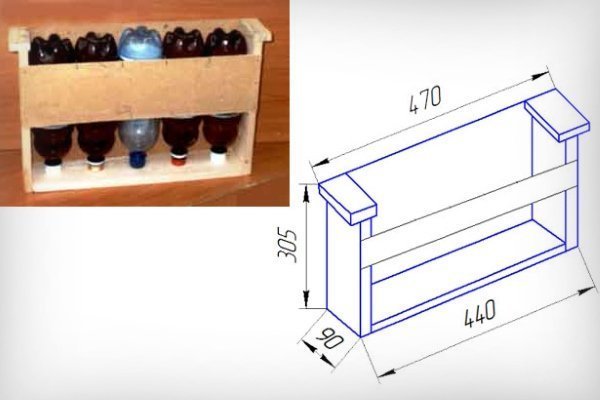

It is worth noting that the vertical feeder can be made of a box type, as shown in the photo:

In this case, it is necessary to make several feeders that will need to be installed in a ready-made cassette, which must be attached near the bee nest.

It is better to use a bottle ceiling feeder in the fall, since during this period bees need concentrated viscous syrup. In the spring, they need water, so the feeders need to be filled with liquid food. It will quickly flow out of the bottle container, which is unacceptable, so you will have to use a different type of feeder.

Homemade bird feeders from cans

Every household has a tin or glass jar. It can also be used to make a homemade feeder using the instructions below.

From a tin can

It would seem that a tin can from canned food is an unsuitable material for making a feeder, but this is not at all the case, since this material has a number of advantages:

- has thin walls that conduct heat well, so the food in the tank does not freeze for a long time;

- easy to clean, which makes it much easier to care for the feeder.

To make a feeding tank, it is better to choose wide and small jars. The instructions are as follows:

- Wash the jar using a detergent, then wipe dry and add fertilizer.

- Cover on top cotton cloth so that its edges reach the middle of the jar. Alternatively, you can use cheesecloth, but it will need to be folded in 3-4 layers.

- To prevent the fabric from slipping, secure it with an elastic band.

- Turn the container over and place it above the nest above the frames. For better access to the food, it can be slightly raised by placing bars underneath it. In this case, small gaps must be left.

From a glass jar

In this case, the principle of action is almost the same. The instructions are as follows:

- Prepare a 1 liter glass jar and pour the nutritious syrup into it.

- Fold a large piece of gauze into 8 layers, moisten with water and squeeze out, then apply to the neck of the jar and tie or secure with an elastic band.

- Place plywood on top of the gauze, then turn the jar over and place it on the top platform of the hive. After that, the plywood can be removed. The syrup will gradually seep through the gauze, so the bees will be able to feed themselves.

From a bucket

Bee feeders are also made from plastic buckets. The principle is the same as with jars. Take a bucket with a tight-fitting lid so that it does not leak after turning over.

Holes no more than 1-1,5 mm in diameter are drilled in the lid (if the drill is thicker, when using a 5-10 l bucket, the liquid will slowly flow out under the force of gravity), syrup is poured in, the bucket is closed and turned over onto the frames. It is used only in multi-hull hives or as an external feeder.

Instructions for making a ceiling bird feeder

A similar box-type reservoir is universal and can be made by beekeepers who have carpentry skills.

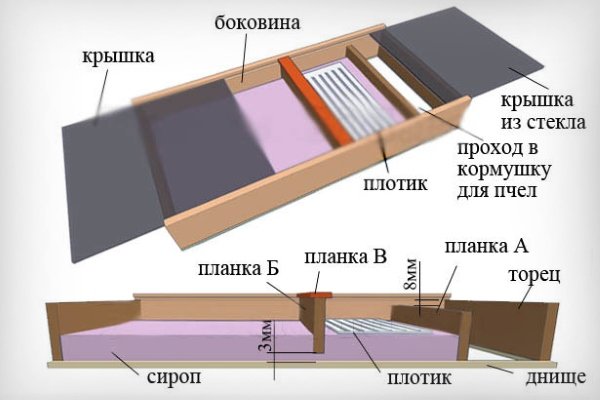

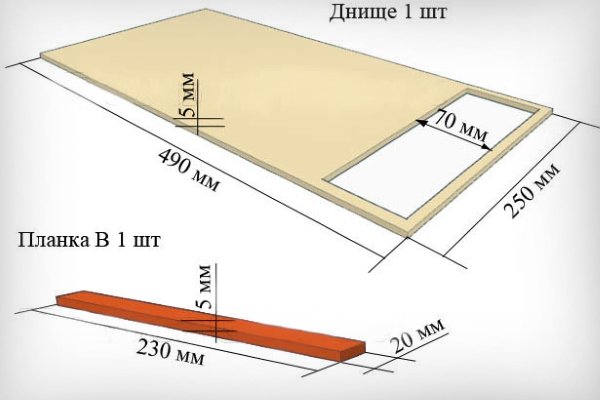

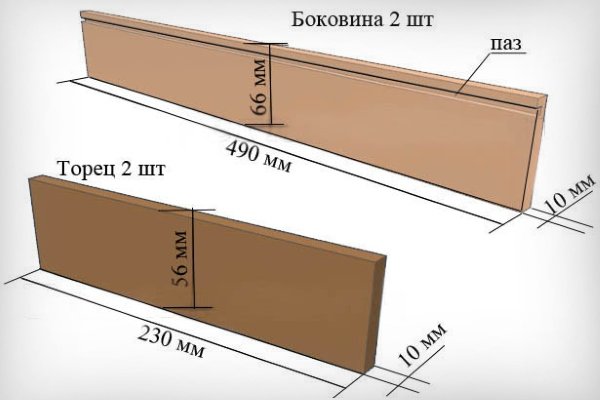

Its structure is as follows:

This feeder is a box, the length of which corresponds to the length of the hive from the back to the front wall.

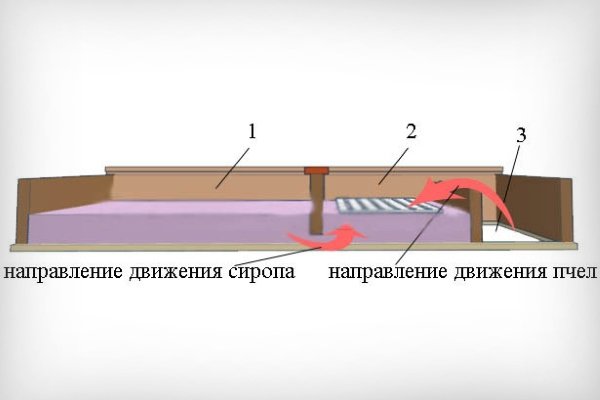

It is divided into three sections, which can be seen in the diagram:

Let’s find out in more detail what these departments are:

- The compartment where you need to pour the syrup.

- A feeding compartment with a raft for bees, which can be made from several materials – polystyrene foam, plywood veneer with drilled holes, mosquito netting plastic. The partition that separates the first two compartments should be at a distance of 1-3 mm from the bottom.

- A small compartment through which insects gain access to the feeding compartment. The partition between them should be 8 mm from the top. There is no bottom at the bottom, so the bees have free passage.

Having understood the principle of constructing a feeder, you can make its parts using the following drawings:

When manufacturing a box-type tank, the following recommendations should be taken into account:

- Make grooves on the top of the side walls into which to place the lids.

- The feeding compartment and the passage for the bees should be covered with a common glass lid to allow control over the volume of syrup and the feeding process. The filling section can be covered with a fiberboard lid.

- The end and side walls should be made of wood, and the bottom should be made of fiberboard or plywood, with its smooth side facing the inside of the tank.

- The structure needs to be assembled, glued and nailed or screwed together. It is advisable to use sealant and PVA glue with the addition of fine sawdust.

- The joints should be treated with wax or mastic made from equal amounts of rosin, paraffin and wax. The hot composition should be applied to the walls and grooves of the structure, and then heated with a blowtorch. Thanks to such manipulations, the feeder will be completely sealed.

The finished structure must be installed directly into the folds or onto the base. In the second case, it is necessary to provide an opening in advance through which the bees can access the syrup.

A simple feeder made from a polyethylene (food) bag

To create an economical version of the feeder, you can use a regular medium-sized food bag.

You need to act in this way:

- Pour the syrup into a clean bag and then tie it tightly.

- Open the lid of the hive and put out the prepared bag.

- Using a syringe needle, make 7-10 holes in the bag.

- Close the lid of the hive.

How to make a feeder from foam?

It is better to choose a material that is used for packaging furniture and equipment, but you will have to refuse from loose construction foam. In addition, it is worth considering that good material does not smell.

To make a feeder you need to prepare:

- foam sheet;

- a conical container made of food-grade plastic with a diameter of 20 cm (the neck of a plastic bottle);

- calico fabric;

- knife;

- rubber band.

Having prepared everything you need, you can begin assembling the structure:

- Cut a disk out of foam plastic 3 cm thick, which should completely correspond to the diameter of the bottle neck. For this, you can use a heated knife or wire.

- Apply the disc to the bottleso that their surfaces are in the same plane.

- On the outer part of the disk make small grooves 5 mm wide so that they run perpendicular to each other from one edge to the other. The distance between them should also be 5 mm. For convenient cutting of grooves, it is better to use not a knife, but a melted hot metal rod.

- In the central part of the disk prepare several holes with a diameter of 7 mm, and then melt 4 grooves on its sides, the depth and width of which should be 5 mm.

- If the feeder has a large diameter or the foam is not strong enough, you will need to increase the strength of the structure. To do this, you need to install a spacer between the disk and the bottom of the neck. To make a spacer, you can use a plastic bottle, cutting off its bottom and neck to get a cylinder. Along its edges, you need to make a groove for the passage of air and food.

- Make a filter using calico fabric. You need to cut a circle out of it, the diameter of which is several centimeters larger than the diameter of the container. Fill the feeder with syrup, and then secure the prepared fabric with an elastic band. Its folds need to be straightened, and then turn the structure upside down and install it over the baking sheet on the slats.

- If the syrup spills out, then the filter is too thin. To allow less feed to pass through, you can use a cloth folded in several layers. If the surface of the filter remains dry, it means that it is too dense, so it will need to be replaced with a thinner cloth.

Ideally, a little syrup should come out through the filter – no more than 1 tablespoon.

Making an over-frame feeder Vasilek

Vasilek is a type of over-frame feeder in the form of a rectangular container, the interior of which is divided by a partition.

In the center of each section there are special “volcanoes”. They need to be covered with glasses or plastic buckets with a capacity of 500 ml. The finished structure needs to be installed on the lid of the hive or on the roof.

When constructing the Vasilok, it is better to use transparent plastic, as it will increase the feeding rate of insects and is easy to clean.

Buy or make?

Beekeepers can argue endlessly about whether to make bee feeders themselves or buy them. Several decades ago, beekeepers almost always made all their equipment in their own workshops.

A purchased item costs money, you have to go to get it or wait for delivery when ordering, and paying for a feeder that you use a couple of weeks a year is not the smartest decision.

Making a homemade one takes up to an hour and a half and a little material, while the simplest bee feeder – made from a jar – will take ten minutes.

Recommendations

When making bird feeders with your own hands, preference should be given to natural or environmentally friendly materials.

To make the right choice, you should take into account some nuances:

- If polyethylene material is used, it is better to choose transparent food grade polyethylene, as it contains fewer harmful substances.

- It is better not to use colored polyethylene and plastic materials, as they are made from recycled materials.

- One of the cleanest and safest materials is polystyrene foam.

There are many bee feeding designs that are safe for insects and easy to use. To save money, you can easily make a feeder yourself by choosing environmentally friendly materials and reading the instructions and drawings provided.